|

| ............................................................................................................................................... >> Weighing Systems |

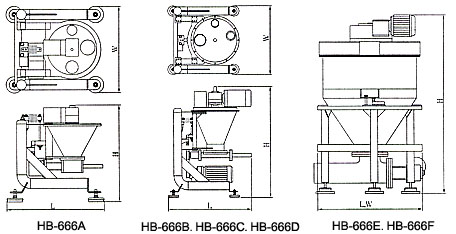

| >> HB-666 SERIES ................................................LOSS IN WEIGHT FEEDING SYSTEM | |

| LOSS-IN-WEIGHT FEEDERS | |

|

The HB-666 is designed for continuous volumetric and gravimetric feeding systems of bulk solids. Such as, granulates, powders, flakes, chips, pellets, and fibers......etc. The system is applied to measuring and feeding bulk solids with high accuracy by control and supervisory systems for continuous weighing and feeding systems. By the way there are available in three configurations of feeder elements which are single screws, twin screws, vibro feeders or Belt feeders to meet any industrial feeding application, particularly in the plastic, chemical, food, detergent, and pharmaceutical industries. The HB-666 series L.I.W Feeder is designed with feed hopper, agitator, vertical rotary, feed element, extension hopper and supporting structure. Gravimetric feeders are completed by two weighing modules. The vertical rotary agitator moves the material in the hopper and ensures safe material flow into the feed element. Feed elements are designed as single-shaft or dual-shatt spirals and screws. |

|

| For adoption to feed rate and application, the extension hopper is available in various sizes. The weighing modules of the gravimetric feeder consist of hermetically sealed precision load cells in strain-gauge technical with integrated overload and anti-rotation protections. | |

| AVAILABLE IN TWO CONFIGURATIONS FEEDING WHICH ARE CONTINUOUS CONSTANCY FEEDING OR BATCHING OPERATION | |

| >> Continuous constancy Feeding Type | |

| Loss-in-weight

feeding involves a continuous flow of dry material into a process. Feed

rates are expressed in units over time, such as 100 kilograms per hour rather

than batch sizes such as 10 kilograms in 5 minutes. Loss-in-Weight Feeding

deviations are better than |

|

| >> Batching Operating Type | |

| For batching type operating that the feeder delivers the material into a container or down stream equipment. Such as mixer, conveyor or service tank ... Etc. When Loss-in-Weight Feeder Feeding to be reached previously preset each batch weight (kg/batch). This is the most accurate operation type of batching with deviations as low as (0.1~0.25% depending on the material and desired batch rate. | |

| >> Feature | |

|

|

| >> TECHNICAL SPECIFICATION | |

| Feed Principle | Gravimetric (Loss-in-Weight Feeder)/Volumetric |

| Feed elements | Single

screws/or twin screws/ or vibro feeder. *Depends on material request to design. |

| Discharge aid | Vertical rotary agitator |

| Parts in contact with materials | Stainless steel |

| Material Temperature | -30 |

| Ambient Temperature | -10 |

| Bulk Density | 0.1 to 1.2t/dm3 |

| Feed Rate | 0.8L to 3700L/HR |

| Feed Accuracy | |

| Feed Constancy | |

| Drives | 1/4 or 1/2HP AC motor with AC inverter/ 1/4 or 1/2 HP DC motor with SCR motor speed controller. |

| >> HB-666 Series Loss-in-Weight Feeder Theoretical Feed Rates |

|

Model

|

Base

Hopper (L) |

Screw

Size (mm) |

Motor

Output (kw) |

Min.

Speed (r/m) |

Max.

Speed (r/m) |

Min.

Rate (l/hr) |

Max.

Rate (l/hr) |

Min.

Rate (kg/h) |

Max.

Rate (kg/h) |

|

HB-666A

|

6

|

12.7

|

0.04

|

12

|

120

|

0.4148

|

4.1810

|

0.2676

|

2.6759

|

|

HB-666B

|

20

|

17

|

0.18

|

12

|

120

|

0.7966

|

7.9668

|

0.5098

|

5.0987

|

|

23

|

0.18

|

12

|

120

|

2.2349

|

2.2349

|

1.4303

|

14.303

|

||

|

HB-666C

|

40

|

37

|

0.37

|

12

|

120

|

8.9992

|

8.9992

|

5.7594

|

57.594

|

|

63

|

0.37

|

12

|

120

|

64.213

|

64.213

|

41.096

|

410.96

|

||

|

HB-666D

|

120

|

87

|

0.75

|

12

|

120

|

126.79

|

126.79

|

81.151

|

811.51

|

|

123

|

0.75

|

12

|

120

|

368.94

|

368.94

|

236.12

|

2361.2

|

||

|

HB-666E

|

500

|

123

|

0.75

|

12

|

120

|

368.94

|

368.94

|

236.12

|

2361.2

|

|

146.6

|

0.75

|

12

|

120

|

970.28

|

970.28

|

620.1

|

6201

|

||

|

HB-666F

|

750

|

146.6

|

0.75

|

12

|

120

|

970.28

|

9702.8

|

620.1

|

6201

|

|

199.5

|

0.75

|

12

|

120

|

2089.6

|

20896

|

1337.3

|

13373

|

|

1)

Theoretical feed rates assume 100% efficiency. Reference Dimensions |

|

| >> HB-666 Series Loss-in-Weight Feeder Theoretical Feed Rates |

|

MODEL

|

BASE

HOPPER (L)

|

L

(mm)

|

W

(mm)

|

H

(mm)

|

|

HB-666A

|

6

|

588

|

515

|

578

|

|

HB-666B

|

20

|

792

|

652

|

1,055

|

|

HB-666C

|

40

|

845

|

652

|

1,162

|

|

HB-666D

|

120

|

845

|

812

|

1,505

|

|

HB-666E

|

500

|

1,20

|

1,120

|

1,910

|

|

HB-666F

|

750

|

1,320

|

1,320

|

2,015

|

| >> Physical Dimension | |

|

|

| All

these advantages combined in the HB-8234 Series measuring system! |

|

|

|

|

|

| ...................................................................................................................................>> Back |

|

|

|

HOLBRIGHT

WEIGHING SYSTEMS CD., LTD.

|

|

4F,

No. 31, Lane 21 Min Chuan East Rd. Sec. 6 Nei Hu. Taipei. Taiwan R.O.C.

|

|

TEL:

886-2-8792-0786 FAX: 886-2-8791-2380

|

|

E-MAIL:

hobright@ms11.hinet.net

|

|

http://www.holbright.com.tw

|