|

| ............................................................................................................................................... >> Weighing Systems |

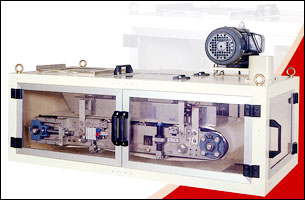

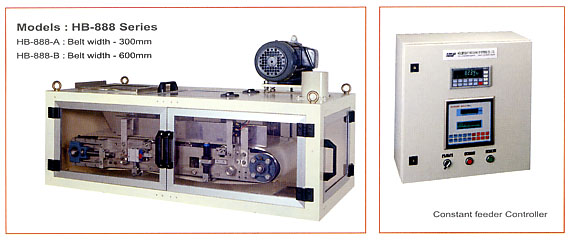

| >> HB-888 SERIES A/B ......................................... CONTINUOUS WEIGH FEEDER SYSTEMS | |

| FOR THE AUTOMATION OF POWDER AND BULK SOLIDS | |

|

The

model HB-888 weigh feeders are designed for continuous of a weigh feeding

system. Which will control and monitor the flow rate of bulk materials,

such as minerals, chemicals, grains, plastic powders or a variety of other

bulk materials. |

|

| >> STANDARD EQUIPMENT FEATURE | |

|

|

| >> ACCURACY | |

|

Holbright has designed a precision weigh feeder system to continuously and repeatable measure weight and belt speed, calculate rate and compare it to set point, providing or monitoring. Flow rate with an accuracy up to 0.25%-1% of set rate at two sigma. |

|

| >> DURABLE CONSTRUCTION | |

|

The weigh feeders are designed by heavy duty construction. With considerable fewer moving parts to ensured trouble free operation and lower maintenance. Constructed primarily of stainless steel, feeder components are designed and manufactured to meet the regions of a harsh industrial environment demanding requirement. |

|

| >> A VARIETY OF CONFIGURATION | |

| Because

most of the feeders are installed in harsh aggressive environments and every

application has its own special requirements, we offer with a wide range

selection of standard and optional construction. These include stainless

steel, carbon steel, galvanized, totally enclosed and open frame...Etc. The HB-888 is available in either 300m/m, 600m/m, size and can be supplied in a variety of configurations. |

|

| >> SELF CONTAINED PRECISE WEIGHING MODULE | |

|

Holbright designed a self contained, precise weighing module for use in repeated shock loading where fast weighing and setting times are required.

|

|

| >> EASY FOR MAINTENANCE | |

| The model: HB-888 has designed, easy of maintenance in all aspects of engineering. Because of these built-in features, the feeder requires less down time for maintenance, repair, or replacement of parts. Such as easy belt change, easy belt adjustment, easy access and disassembly, removable front and back doors, free-maintenance cog belt drive, sealed bearing, weighing module, automatic belt tensioning......etc. | |

| >> GRAVIMETRIC FEEDER APPLICATIONS | |

|

There are many different proportioning systems where continuous weighing equipment can be used. Some examples of these systems are:

|

|

| >> The HB-888 Wide Range Belt Weighing Feeder | |

|

|

| DIMENSIONS IN INCHES (AND MILLIMETERS); FEED RATE IN POUNDS PER MINUTE (AND KILOGRAMSPER MINUTE) | |

|

MODEL

|

Feed

rate range

|

Belt

width

|

In

Feed To Discharge

|

Power

Supply

|

Inlet

Dim.

|

Discharge

Dim.

|

|

HB-888A

|

4-230

(1.8-105) |

12"

(300 mm) |

30"

(770) |

110-240VACx3

|

7.8x7.8

(200x200) |

13.8x9.8

(350x250) |

|

HB-888B

|

8-460

(3.6-210) |

24"

(600 mm) |

30"

(770) |

110-220VACx3

|

18.9x9.4

(480x240) |

25.6x9

(650x230) |

|

BASED

ON 40 LBS PER CUBIC FOOT MATERIAL (640KG PER CUBIC METER)

|

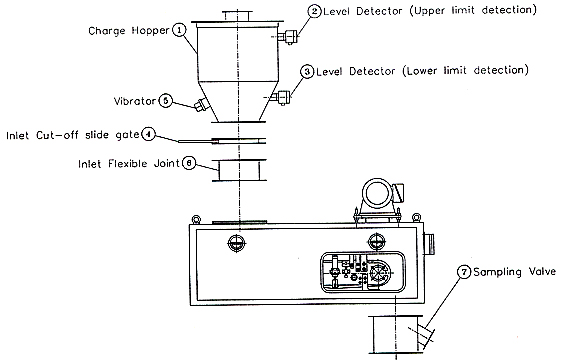

| Options for Belt Weighing Feeders | |

| >> Feeder Accessories |

|

|

|

| ...................................................................................................................................>> Back |

|

|

|

HOLBRIGHT

WEIGHING SYSTEMS CD., LTD.

|

|

4F,

No. 31, Lane 21 Min Chuan East Rd. Sec. 6 Nei Hu. Taipei. Taiwan R.O.C.

|

|

TEL:

886-2-8792-0786 FAX: 886-2-8791-2380

|

|

E-MAIL:

hobright@ms11.hinet.net

|

|

http://www.holbright.com.tw

|