|

+ Home > PRODUCTS > Weighing indicator > HB-8260

HB-8260 HB-8260

Smart Digital Type Weight Controller

.jpg) Faster, easier scale calibration. (1/4 or less of conventional calibration time) Faster, easier scale calibration. (1/4 or less of conventional calibration time)- Quick and easy recalibration in the event of a load cell replacement.

- Less maintenance and calibration cost with no in-scale physical adjustment. (As opposed to an analog system)

- Continued use of standard, customer preferred load cells.

- Upgrading! Easy conversion from an analog scale system.

- Digital load cell signals increase your system performance and accuracy by being more resistant to outside interference and influences (RFI&EMI).

- Strong digital signals do not degrade over long distance.

- Each load cell communicates individually with the HB-8260 Controller.

- The HB-8260 must be ordered with HB-SDJB4 or HB-SDJB8.

Standard Features:

- Digital Transmission - HB-8260 can be composed with those digital products as below: HB-DLC HB Digital Load Cell HB-SDJB-4P 4-channel Smart Digital Junction Box (can be connected 1 to 4 LCs) HB-SDJB-8P 8-channel Smart Digital Junction Box (can be connected 5 to 8 LCs) Whether new or former weighing systems, using HB-8260 series products can help you meet full digital weighing system demand with less cost.

- Stable Performance - the weight value signal transform to digital signal in the weigher side then convey to the HB-8260; it is different from traditional weighing system trans messages via weak analog signal therefore HB-8260 enhances the ability of anti-interference and transmission distance, the weighing system becomes more stable.

- Convenient Calibration - Each LC of the multi-LCs weighing system does digital transmission itself; it is different from traditional weighing system's LCs parallel connection and decreases the difficulty in calibration substantially.

- Easy Repair - Each LC's load point has it's own weight value indication in the multi-LCs weighing system; therefore the user can differentiate the weighing system's deviation or LCs' bug. It is convenient to maintenance and repair.

- Multi-Compatible - The Smart Digital Junction Box can be connected with any brand, kinds of Analog Load Cell then upgrade the traditional Analog weighing system to Digital weighing system directly.

- Data Collection - The HB-8260 is provided with DATA Logger design, the DATA Logger design can analyze and online detect by collecting each Digital LC's data.

- Smart Detection - The HB-8260 can judge the In/Out bound Truck belongs usual freight-truck, aqua-truck or there is a stiff wind while weighing, to start the related software to make the user can receive stable and accurate Weight Value quickly and effectively.

- Weighing Independently - The HB-8260 is provided with complete and independent Truck Weighing Function--- Single Weighing & Twice Weighing Capacities allow the user can enter ID (Truck's No.), Memory and printout Label. The printout content including of In/Out bound time, Date, Serial No., ID (Truck's No.), Gross, Tare and Net.

Technical Specification:

| HB-8260 |

Display Specifications |

| Display |

128X64 dot matrix backlight LCD Module |

| Weight Indication |

8 digits, 10mm Height |

| Message Indication |

16 digits X 4 line. 5X7 dots digit display |

| Zero Indication |

▽ZERO Center of Zero (±0.25) |

| Tare Indication |

▽TARE Tare Weight Mode |

| Stable Indication |

▽STAB Weigher is stable |

| Gross Indication |

▽GROSS Gross Weight Mode |

| Net Indication |

▽NET Net Weight Mode |

| Setting Indication |

▽FUNC F-Function Setting Mode |

| Display Resolution |

300~60,000 |

Interface Specifications |

| CAN BUS Interface |

Standard 2 Ports. CAN Port 1 & 2 |

| PS2 KB |

The HB-8260 can be connected with PS2 KB for Operation, Entering, Calibration and co-work with the Mainframe's Keyboard |

| Centronics Parallel Interface (OP-01,Parallel Port) for printer |

| Type of Interface:Centronics Parallel Interface |

| Signal Level: TTL-Levl |

DIO Interface:(Standard 1 Port, DIO Port 1)& (OP-03, DIO Port 2)

External Input Signals 4 points of DI, Contact input or open-collector input isolated with photocouplers

External Output Signals 4 points of DO, open-collector output isolated with photocouplers |

Control Mode: Mode 0: User Defined I/O Mode Mode 1:Hopper Charge Mode

Mode 2:Hopper Discharge Mode Mode3:Truck Scale I/O Mode |

| Analog Interface (OP-03, AO Port) |

| Conversion Method: 14bits D/A Conversion |

| Signal Accuracy: 1/10000 |

| Driving Capability: 4-20MA 350Ω Load (Max) |

| RS-232 Interface: (Standard 1 Port, Serial Port 1) & (OP-04, Serial Port 2) |

| RS-485 Interface (OP-05, Serial Port2) |

| USB Interface (OP-06, Serial Port2) |

HB-Smart Digital Multi-Channel A/D Conversion Unit (HB-SDJB)

Model |

HB-SDJB4/8 (AC) |

HB-SDJB4/8 (DC) |

| A/D Channel |

4 or 8 independent A/D Channel

(24 bits delta sigma A/D) |

4 or 8 independent A/D Channel

(24 bits delta sigma A/D) |

| Conversion Rate |

128 samples/second |

| Internal Resolution |

16,000,000 divisions |

| Graduation Resolution |

60,000 divisions |

| Signal Sensitivity |

0.1u V/graduation (min) |

| Signal Range |

0.5mV/V to 3mV/V |

| Load Cell Excitation |

5±0.25VDC |

| Drive Capability |

120mA for up to 8 (350Ω) load cell |

| Power Supply |

100~240±10VAC X50/60Hz Switching Power |

DC 20V~30V, 5w |

| Max. Transmission Distance |

Unlimited |

Max Transmission Distance 200m,(AWG 22)

*Connect 2 AWG22 line can achieve 370m |

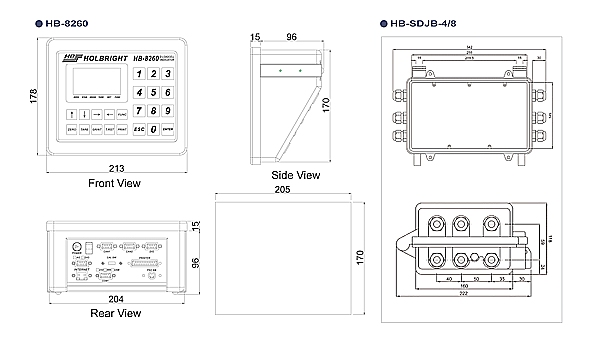

Physical Dimensions Outline:

|