|

+ Home > PRODUCTS >Weighing Systems > HB-666 SERIES

HB-666 SERIES HB-666 SERIES

LOSS IN WEIGHT FEEDING SYSTEM

The HB-666 is designed for continuous volumetric and gravimetric feeding systems of bulk solids. Such as, granulates, powders, flakes, chips, pellets, and fibers......etc. The HB-666 is designed for continuous volumetric and gravimetric feeding systems of bulk solids. Such as, granulates, powders, flakes, chips, pellets, and fibers......etc.

The system is applied to measuring and feeding bulk solids with high accuracy by control and supervisory systems for continuous weighing and feeding systems. By the way there are available in three configurations of feeder elements which are single screws, twin screws, vibro feeders or Belt feeders to meet any industrial feeding application, particularly in the plastic, chemical, food, detergent, and pharmaceutical industries.

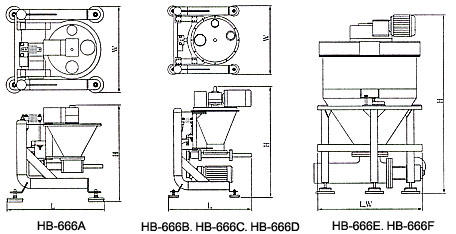

The HB-666 series L.I.W Feeder is designed with feed hopper, agitator, vertical rotary, feed element, extension hopper and supporting structure. Gravimetric feeders are completed by two weighing modules. The vertical rotary agitator moves the material in the hopper and ensures safe material flow into the feed element. Feed elements are designed as single-shaft or dual-shatt spirals and screws.

For adoption to feed rate and application, the extension hopper is available in various sizes. The weighing modules of the gravimetric feeder consist of hermetically sealed precision load cells in strain-gauge technical with integrated overload and anti-rotation protections.

Standard Features:

- Various Feeder elements e.g.

1) Single Screws 2) Twin Screws 3) Vibro Feeders. 4) Belt Feeders

- Batching or continuous constancy feeding control.

- Blending with a group of feeders (master/slave control).

- Feeder with vertical rotary agitator for breaking bridging.

- High accuracy, better than ±0.5%.

- Material of construction made of stainless steel.

- Feed system for volumetric and gravimetric bulk solids feeding.

- Integrated measuring, control, and supervisory performance in controller.

- Heavy duty construction apply in any industrial area.

Technical Specification:

| Feed Principle |

Gravimetric (Loss-in-Weight Feeder)/Volumetric |

| Feed elements |

Single screws/or twin screws/ or vibro feeder. *Depends on material request to design. |

| Discharge aid |

Vertical rotary agitator |

| Parts in contact with materials |

Stainless steel |

| Material Temperature |

-30C to 100C |

| Ambient Temperature |

-10C to 50C |

| Bulk Density |

0.1 to 1.2t/dm3 |

| Feed Rate |

0.8L to 3700L/HR |

| Feed Accuracy |

±0.55 |

| Feed Constancy |

0.5% |

| Drives |

1/4 or 1/2HP AC motor with AC inverter/ 1/4 or 1/2 HP DC motor with SCR motor speed controller. |

Physical Dimension

|