|

+ Home > PRODUCTS >Weighing Systems > HB-777 SERIES

HB-777 SERIES HB-777 SERIES

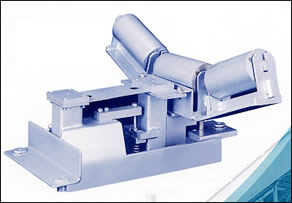

BELT WEIGHERS UNIT

CAPACITY UP TO 5000 METRIC TONS PER HOUR, BELT WIDTHS UP TO 72" (1800m/m)

Belt Weighing unit are used to measure continuous material flows of varying amounts. When weighing material carried by a conveyor, one or more of the conveyor idlers is replaced by a weighing unit with idlers having the same geometry as the adjacent idlers. Weighing units, available in various versions, comprise the weighing module for accommodating user's idler set, load cell is equipped with mechanical and shock overload protection devices to prevent damage to the load cell. Belt Weighing unit are used to measure continuous material flows of varying amounts. When weighing material carried by a conveyor, one or more of the conveyor idlers is replaced by a weighing unit with idlers having the same geometry as the adjacent idlers. Weighing units, available in various versions, comprise the weighing module for accommodating user's idler set, load cell is equipped with mechanical and shock overload protection devices to prevent damage to the load cell.

Standard Features:

- Extremely user friendly operator interface, including self-prompting instructions and messages.

- Sealed membrane full-function keyboard.

- Multi-function display: including 8 digit 10mm high upper read-out for numeric data, 128x64 dots LCD display full alpha-numeric lower read-out messages and instructions. Also 8 LED status indicators for annunciation of alarms, inputs, etc.

- Total password security for protection of calibration constants and re-rate (capacity re-program ming) parameters.

- Electrically isolated inputs and outputs. Additional inputs and outputs available with expansion modules.

- Max. 16 dry contact input or NPN open collector transistor input. (option up to 32 D/I)

- Max. 8 NPN open collector transistor output (option up to 16 D/O)

- Panel mount and Wall mount enclosures available.

- Automatic belt deviation monitoring. / Automatic belt slip monitoring.

- User selectable English or Metric units of measurement.

- Remote operation keyboard for systems.

- Printer interface is available.

- Chart recorder interface is available.

- Excellent immunity to RFI and EMI.

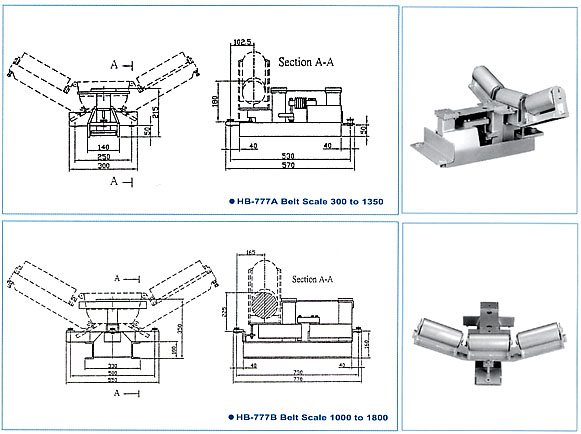

Physical Dimension

|